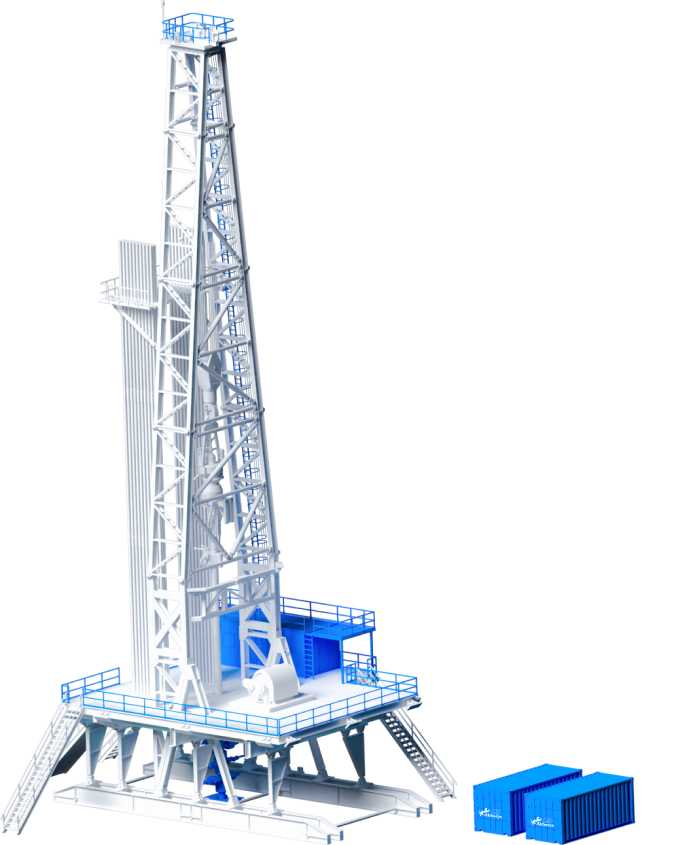

Comprehensive safety solutions in petroleum industry

Comprehensive safety solutions in petroleum industry

15years in business

67projects completed

Years of experience

Since our foundation, we have become one of the leading and effective service providers in hydrogen sulfide safety.

We see a future in which technology will help people in dangerous and life-threatening circumstances return home safely to their families. We are building up our strengths in the core market and heading to new industries. We come to where our safety techs, experience and knowledge are needed.

Wide range of gas safety services

QHSE-Akbarys is a leading provider of gas safety services in the CIS and neighboring countries.

Our experience covers a great range of operations related to high concentrations of H2S and the most common toxic gases such as SO2, CO, CO2 and CH4.

Hydrogen sulfide is a challenge in the oil and gas industry because of the its high concentration found upon drilling, testing, workover and production operations.

We are professionals in the early detection of the most common toxic and explosive gases. In other words, the substances being encountered at hazardous facilities in the oil and gas industry, including H2S, SO2, CO, CO2 and CH4. Our advanced systems provide early gas detection, public address and data collection by recording on all specific devices.

When working in a toxic chemical environment, the use of gas detection systems is a vital precaution. This equipment is focused on early warning of low gas concentrations in the air. It allows site personnel to response immediately and leave the hazardous area before the concentration of the substance turns lethal.

- QHSE-Akbarys gas detection system includes 3 types of solutions:

- Stationary wireless gas detection systems

- Portable multi-gas analyzers

- Personal gas analyzers

When dealing with extreme gas concentrations or in harsh environment with low oxygen levels, sampling pumps with tubes for a wide range of toxic substances can be used.

ISO standards

Over last 10 years the company has been successfully maintaining international standards such as ISO 9001 for quality management systems, ISO 45001 for health and safety management systems and ISO 14001 for environmental management systems.

We are constantly improving our integrated environmental management. We are keeping an eye on emission reduction. Effectively managing and controlling major environmental risks.